Experience the perfect balance of performance and price with the new Mimosa C6x Lite Edition — built for today, ready for tomorrow.

Many outdoor products claim they are designed for extended temperature ranges, but this does not always mean that they are truly outdoor rugged. There are some design decisions that are standard for any outdoor product. Using galvanized and powder coated metal along with UV treated polymers for example. Often overlooked are a number of critical design elements that ensure long-life operation in the toughest environments.

One way we ensure reliability in an outdoor environment is by testing and rating against an International standard known as IEC 60529. This provides a testing methodology and a rating system consisting of two digits, for example in the case of most Mimosa products, we engineer them to an IP67 rating. “IP” is generally accepted as short hand for “Ingress Protection” and the two digits in the rating specify the level of protection against foreign objects and liquid respectively.

Let’s look at the first digit and how it specifies protection from foreign objects:

| Level | Protection Against Size Object | Effective Against |

|---|---|---|

| 0 | - | No protection against contact and ingress of object |

| 1 | >50 mm | Any large surface of the body, such as the back of a hand, but no protection against deliberate contact with a body part |

| 2 | >12.5 mm | Fingers or similar objects |

| 3 | >2.5 mm | Tools, thick wires, etc |

| 4 | >1 mm | Most wires, slender screws, large ants etc. |

| 5 | Dust Protected | Ingress of dust is not entirely prevented, but it must not enter in sufficient quantity to interfere with the satisfactory operation of the equipment. |

| 6 | Dust Tight | Dust Tight |

Source: Wikipedia

The second digit shows the level of protection against liquid:

| Level | Protection Against |

|---|---|

| 0 | No Protection |

| 1 | Dripping Water Vertically |

| 2 | Dripping Water 15° from Vertical |

| 3 | Spraying Water up to 60° from Vertical |

| 4 | Splashing Water from any Direction |

| 5 | Water Jets |

| 6 | Powerful Water Jets |

| 7 | Immersion up to 1m Depth |

| 8 | Immersion > 1m Depth |

Source: Wikipedia

Mimosa’s Backhaul portfolio* and all of our Access Point products are rated to IP67. This means that according to the tables above, that they are completely protected from dust and have been tested immersed in up to a meter of water.

*B5-Lite is IP55 rated

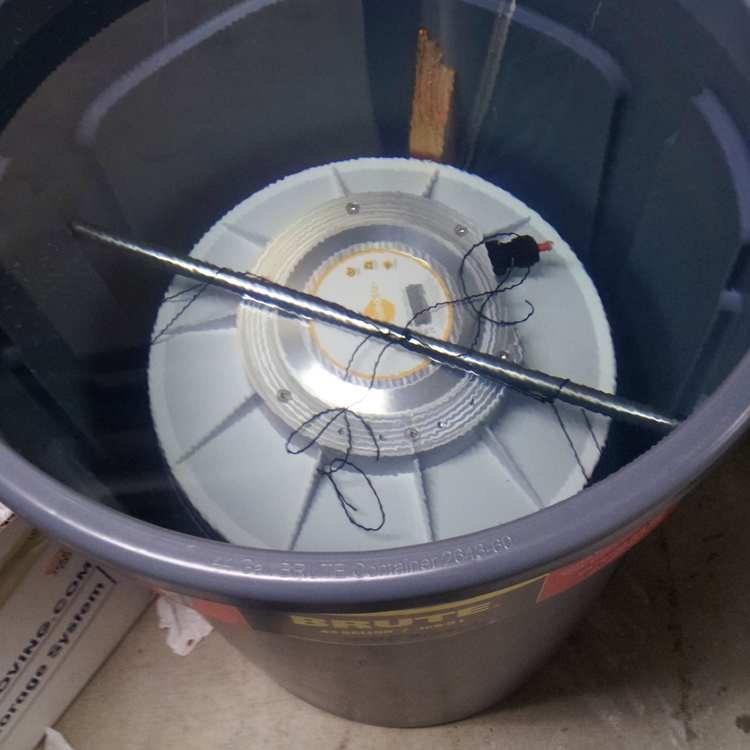

As shown, an IP67 rated product is sealed against dust and water. To be rated at IP67, the most rigorous test is the water immersion test, where the product is inserted in 1 meter of water for 30 minutes, while powered! It has to be demonstrated that at the end of this 30 minute period, no water ingress has occurred. It should be pointed out that this level of testing is not the same as rating a product for continuous use underwater, which would require IP68. As 5 GHz radio waves do not propagate through water, this level of IP rating would be of no use.

An early B5 prototype immersed in water

To test for protection against foreign objects, a probe at the stated minimum intrusion size is used to attempt to enter the product. To test for dust ingress, a sealed chamber which circulates loose dust particles is used.

To ensure integrity of our devices on an ongoing basis, one of the final tests we perform on each individual product before it rolls of the production line is a leak test. To conduct the leak test, we seal the Ethernet port and connect to an air pressure hose to an open port on the product (more about this below). We then apply air pressure to the inside of the product and observe the pressure level for 60 seconds. If we see any more of a 0.1% pressure drop from the maximum pressure, then the product is said to have a leak and is sent back for remediation before retesting.

An assumption that many make when they see the joining of two polymer surfaces in our products is that we glue these together. Two examples are the radome cover on the B5 or the top cover on an A5. We actually use ultrasonic welding, which is where two polymer surfaces are pushed together with force, then rapidly vibrated. This in effect causes the two surfaces to melt and fuse together. This is important to maintain an air-tight seal. Any issues with the seal would be detected at the leak test stage.

Out

Current guesses from our customers have included a reset switch, a fiber port or an extra antenna. This is what we refer to as a Gore gland. It is made by the same company that invented the Gore-Tex jacket. It is a one-way membrane that is designed to allow gases within a unit to pass from inside to outside, but not the other way around. This allows the air pressure inside and outside a radio to equalize. Where this is important is avoiding the buildup of condensation inside a product, which frequently occurs due to rapid changes in temperature as a result of the day/night cycle. The Gore gland is removed during the testing process and we insert a valve to introduce pressure to test for leaks. It should not be removed by the user as it exposes the inside of the product and there is a risk of losing or misplacing the gland.

The scourge of any outdoor operator is water ingress in Ethernet ports, which over time can cause corrosion of the Ethernet port. This eventually causes the Ethernet to stop functioning, which is particularly concerning when the device is powered over Ethernet. The majority of our Backhaul products and our Access Points come with an IP67 Ethernet gland. When installed correctly, this will isolate the Ethernet port from the external environment. We tested many prototypes of this gland to get the optimal design, and a key criteria was the ability to pass a pre-terminated Ethernet cable through the gland during install.

Our connectorized backhaul radios have two Type-N coaxial connectors, and our connectorized access point radio has four connectors. It is important to seal these connectors correctly using mastic tape. We supply a high-quality mastic tape with our radios to ensure the RF connection between our product and a dish jumper cable is sealed from moisture.

There is a cost trade-off when deciding to which IP level to build a product. The B5-Lite and C5 are rated to IP55. This means they have been tested to ensure that objects and most particles of dust, along with water sprayed at high pressure, do not enter the product and cause any degradation of product performance. An IP55 rating does not impact the ability for the product to be used outdoors in harsh conditions. But the design decisions are driven by the different requirements for a device used for client installs that tends to have a shorter technology refresh cycle, versus a high end backhaul product that is typically installed at higher elevation on towers and more exposed to the elements.

Mimosa perform what we affectionately call the “Shake and Bake” test during the design verification stage of a new product. We take the products and subject them to vibration testing and operating in a chamber at high and low temperatures. Our rated operating temperature for all products is -40°C to +55°C (-40°F to 131°F). An important thing to remember, the internal temperature reported in the Mimosa dashboard will usually be in excess of the ambient air temperature and outside of the stated ranges here. This is because the internal temp is read from the chip within the radio, which is designed to operate at a higher temperature threshold.

Mimosa have seen successful extended use of our products in harsh environments such as deserts, jungles and in areas prone to ice storms. We’re confident that we’ve built a product that will be reliable for years, not matter what is thrown at it by Mother Nature.

Contact us if you have any questions or would like to learn more.